Your Connection to Pipe Joining Solutions

Our highly durable pipe fitting solutions meet every conceivable challenge while accommodating countless business requirements, including thermal movement and seismic solutions.

Engineering Benefits

When installed, Victaulic’s piping components are engineered to take into account numerous environmental factors, from seismic and thermal movement to noise and vibration attenuation.

Accommodating Seismic Movement

Accommodating Thermal Movement

Noise & Vibration Attenuation

Engineering Benefits

When installed, Victaulic’s piping components are engineered to take into account numerous environmental factors, from seismic and thermal movement to noise and vibration attenuation.

Accommodating Seismic Movement

Accommodating Thermal Movement

Noise & Vibration Attenuation

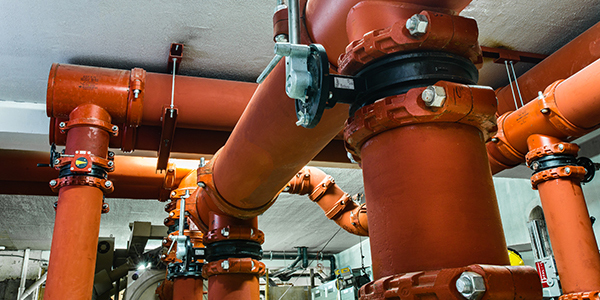

Mechanical Joining

Togetherness — that’s what our Mechanical Joining systems are all about. Gasket Technology and Grooved Technology form the basis for our advanced couplings. All are manufactured to exacting standards and for optimal performance to satisfy your piping requirements.

Mechanical Joining

Togetherness — that’s what our Mechanical Joining systems are all about. Gasket Technology and Grooved Technology form the basis for our advanced couplings. All are manufactured to exacting standards and for optimal performance to satisfy your piping requirements.

Pipe System Installation

Victaulic piping systems are safe, efficient, and cost-effective, eliminating hazardous welding and lowering risk during installation.

Safer System Installation

Compressed Construction Schedules

Simplified Maintenance

Confined Space Installation

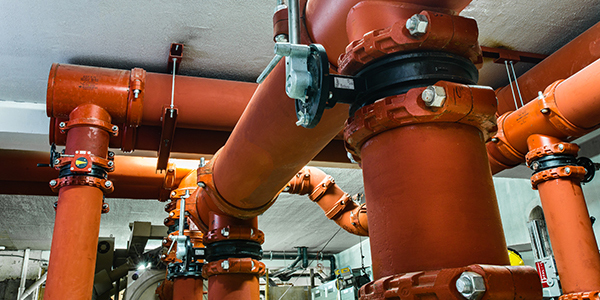

Pipe System Installation

Victaulic piping systems are safe, efficient, and cost-effective, eliminating hazardous welding and lowering risk during installation.

Safer System Installation

Compressed Construction Schedules

Simplified Maintenance

Confined Space Installation